Fabrik in Auto sector

Our commitment goes beyond meeting customer needs; it’s about propelling the automotive industry forward through our products and services. Recognizing the automotive industry’s significance as a vital driver of the economy, we have established a dedicated strategic business unit – automotive (SBU-A). This vertical, within our marketing department, takes a holistic approach, envisioning the sector’s long-term future as we continue to focus on its growth and development.

DEDICATED TO INNOVATION

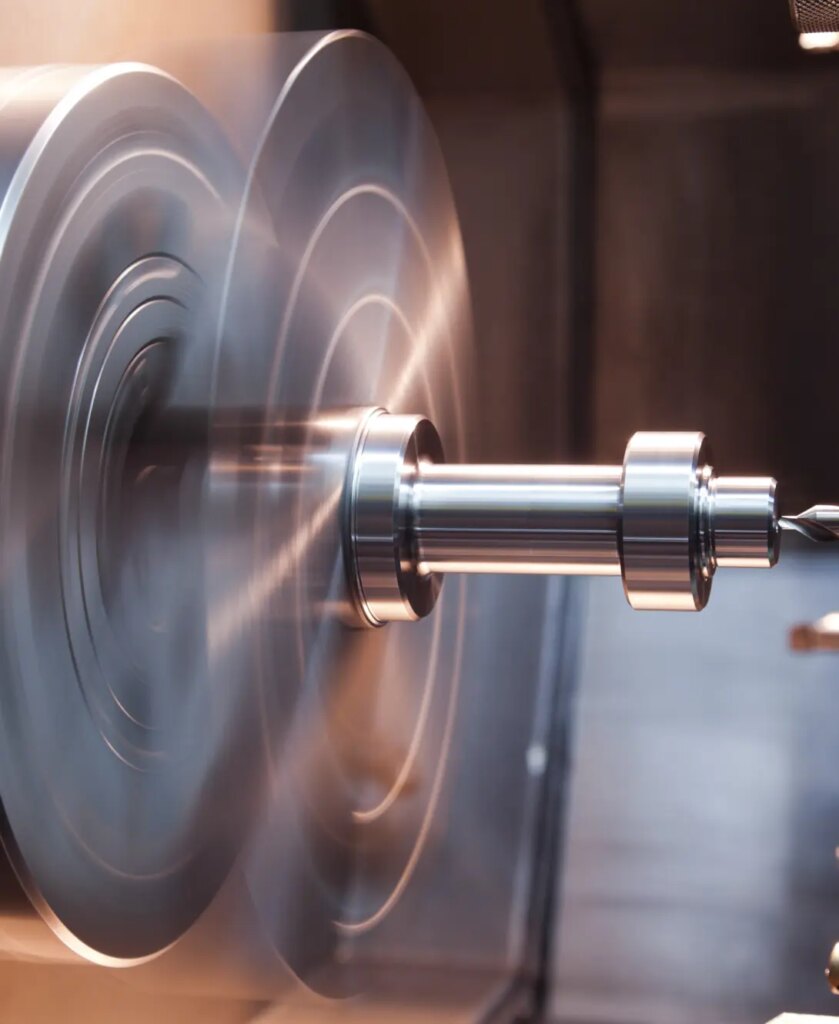

The Fabrik Automotive Center was established with a singular purpose: to provide specialized material and application expertise to assist our automotive customers. Equipped with cutting-edge technology and backed by decades of experience, our commitment is to aid automotive engineers in assessing potential applications and addressing the current challenges and opportunities, such as cost savings, weight reduction, formability, crash energy management, and material availability.

Lightweight Integrated Components

Stainless steel’s reputation for lightweight strength makes it a preferred material choice in various automotive applications. It excels in parts crucial for a car’s performance, including the fuel tank, chassis, and even the bumper.

Additionally, stainless steel is crucial in crafting numerous small components like tubes, brackets, springs, clamps, flanges, and other intricate parts. These more minor elements support the vehicle, connect components, and form the car’s overall structure.

Car Frame

Stainless steel seamlessly blends durability and elasticity, making car frames crafted from this material possess similar strength to many other metal alloys while also being notably lighter. Opting for stainless steel translates to a robust yet lightweight frame, considered one of the most effective supports for a vehicle.

In rigorous testing of austenitic stainless steel grades, the material’s hardening rate was observed to correlate with the deformation rate. In the context of automobiles, stainless steel can absorb more force compared to the typical structural steel often utilized.

Corrosion Resistant Parts

Stainless steel is essential for vehicles, offering corrosion resistance in the face of dirt and adverse weather conditions. It’s a top choice for parts like exhaust systems, which are prone to corrosion, and it currently makes up roughly half of all exhaust systems manufactured. Although less common, stainless steel can also be used for parts like wheels and the lower car structure, reflecting a commitment to higher-quality, long-lasting vehicles.